Industrial Electronics Repair Quality Control is a key component of every manufacturing process. Quality control systems help to identify what is good and bad and corrects mistakes.

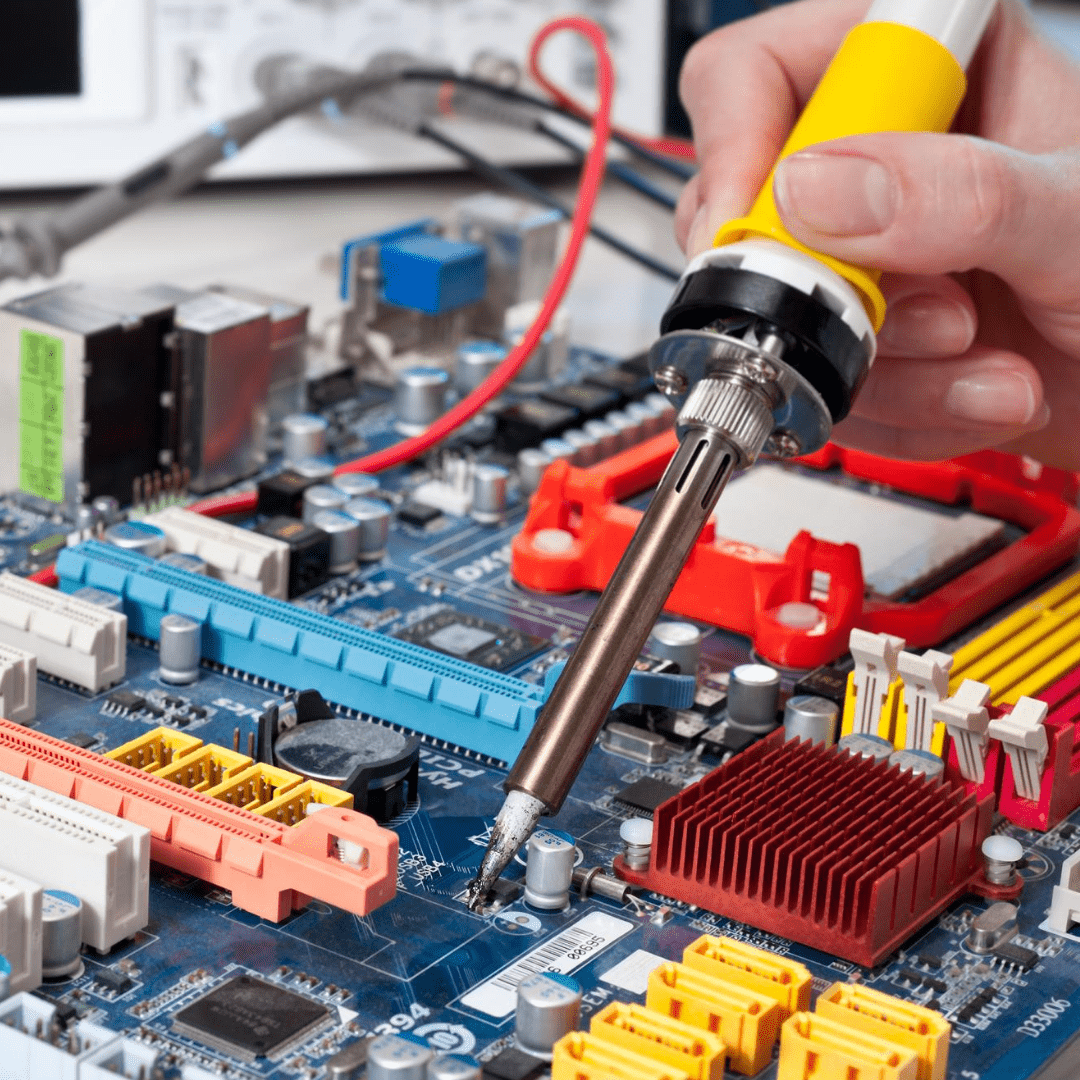

If, for instance, an oily residue appears to be left behind by the soldering traces on your product’s trace, it may be spotted by the QC inspecting team of your customer. There may be a need to re-do the work in this situation.

Very Important

Quality control is a critical process that ensures the consistency and precision across all the products. It includes inspection, testing as well as documentation that identifies defects and deviations from the standards. The program also includes implementing corrective measures to resolve problems that may arise.

Controlling quality for businesses that make electronic products is vital in order to cut costs, reduce risks and maintain a good image. This involves meeting deadlines and delivering on commitments, as well as identifying problems that could arise and solving problems before they can have a adverse impact on the manufacturing process.

It is important to do this as globalization forces firms to boost their manufacturing. Quality products and services will help to build brand recognition, increase efficiency and create an enduring customer base. Businesses will be able to increase their presence and to compete on a global scale. But a poor implementation of a quality control program will result in a myriad issues, including the use of money, human error or omissions, ineffective products and inadequate specification of products.

Reliability, longevity and durability

Through automation and providing precision, industrial electronic devices provide an enormous amount of value to your business on the factory floor. Electronic devices are vulnerable to failings just like every other piece of equipment. They must be properly maintained and repaired by using proactive maintenance programs to fight corrosion.

It’s crucial to repair and maintain electronics to stay clear of the possibility of planned obsolescence. This is why many manufacturers focus on longevity and reliability of their items. It is important not to confuse the term “longevity” with “reliability,” as this is commonly misinterpreted with MTBF numbers (Mean Time Between Faults) of a component.

Repairability increases can result in the development of new models for business, like devices as a service, Upgrade Plans, Module and Parts Sales, Graded Product Resale and Maintenance Programs. These helps lower emissions from scope 3 and reach net zero as well as other sustainability goals. The development of circular chains could be aided by this.

Standards and Compliance

In the electronics industry There are numerous regulations that must be met to ensure product quality as well as safety. Many of these requirements are time-consuming and costly. sua bien tan These requirements are important for the security of those who consume and the companies that buy these items.

Every quality control program must incorporate the management of risk. This helps to identify potential problems and correct the issues to prevent damage to production processes. Additionally, it is focused on maintaining a low cost and meeting deadlines.

Electronics manufacturers who want to be competitive on the global market must adhere to standards. There are various standards based on the kind of product you have. If your company is a maker of electronic devices that require electricity in order to operate, your company must conform to European Union Regulation 048/2019. It is a condition that your devices must pass inspections and be given a certificate or declaration of quality.

Cost-Efficiency

The quality control of repairs isn’t just important but also a cost-effective way to reduce expenses. It helps companies avoid wasting money and loss. The process and equipment are functioning properly and are running at the appropriate speed in order to stop delays.

Quality control is a key element of repair.

PCB testing is a visual inspection on the PCB in order to check if it’s in accordance with an image – this could help prevent errors such as putting a component in the wrong place. It could also uncover missing components.

Resistors are replaced. These passive elements, which impede electrical current and often act like a resistance to electricity, can be found throughout circuits and can be a frequent victim of damaged electronics. In the event of their failure, a repair center replaces them with exactly the same type of resistors.

An experienced repair facility can provide free inspections of equipment, and will provide estimates for repairs, with no bench fees. Additionally, they will offer a good warranty that covers parts and labor.